Rock grouting is normally done in fissured rock to reduce the flow of water along the joints and discontinuities in the rock.

Common uses

Reduce conductivity/transmissivity via interconnect porosities in an aquifier

Increase resistance against deformation

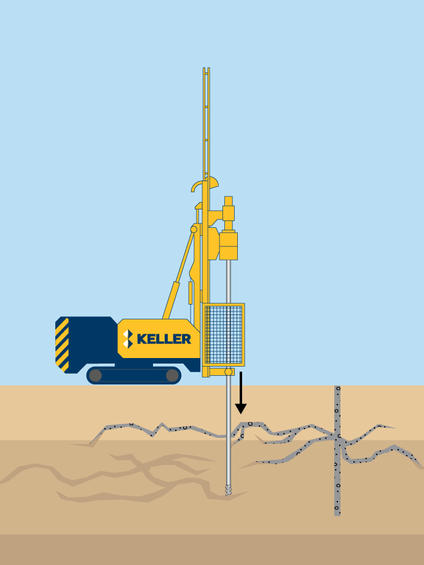

Process

Grout is typically injected in isolated stages from boreholes drilled using rotary percussive drills. Reduction in permeability is a function of the grouting material, the rock and grout design. Rock grouting is typically performed with general purpose, ultra-fine or micro-fine Cement.

Advantages

Can be effective in reducing ground water flows

Reduce pumping costs during basement excavation

Reduced lowering of groundwater levels outside an excavation

Can reduce rock deformation

Quality assurance

Keller has industry leading knowledge of grout materials and mixes and uses the latest drilling techniques to minimise borehole deviation and maximise efficiency. It can also apply sophisticated computerised control and reporting of the grout injection process.